CBR 929 wire keeps melting then blows fuse

#31

That's power wire from starter-solenoid to fuse box. Problem ISN'T any part, it's WIRING. So put every original part you replaced back on bike.

Unless it's brand-new sfactory OEM part bought from authorised dealer, then leave it on. Also remove any and all non-factory wiring and non-OEM electronic part. Like LED winkers and integrated taillights. Installing those things always causes damage that blows fuses endlessly.

Once every non-OEM part has been replaced with original OEM part, then we'll measure each and every single piece of wire in harness to find short.

Unless it's brand-new sfactory OEM part bought from authorised dealer, then leave it on. Also remove any and all non-factory wiring and non-OEM electronic part. Like LED winkers and integrated taillights. Installing those things always causes damage that blows fuses endlessly.

Once every non-OEM part has been replaced with original OEM part, then we'll measure each and every single piece of wire in harness to find short.

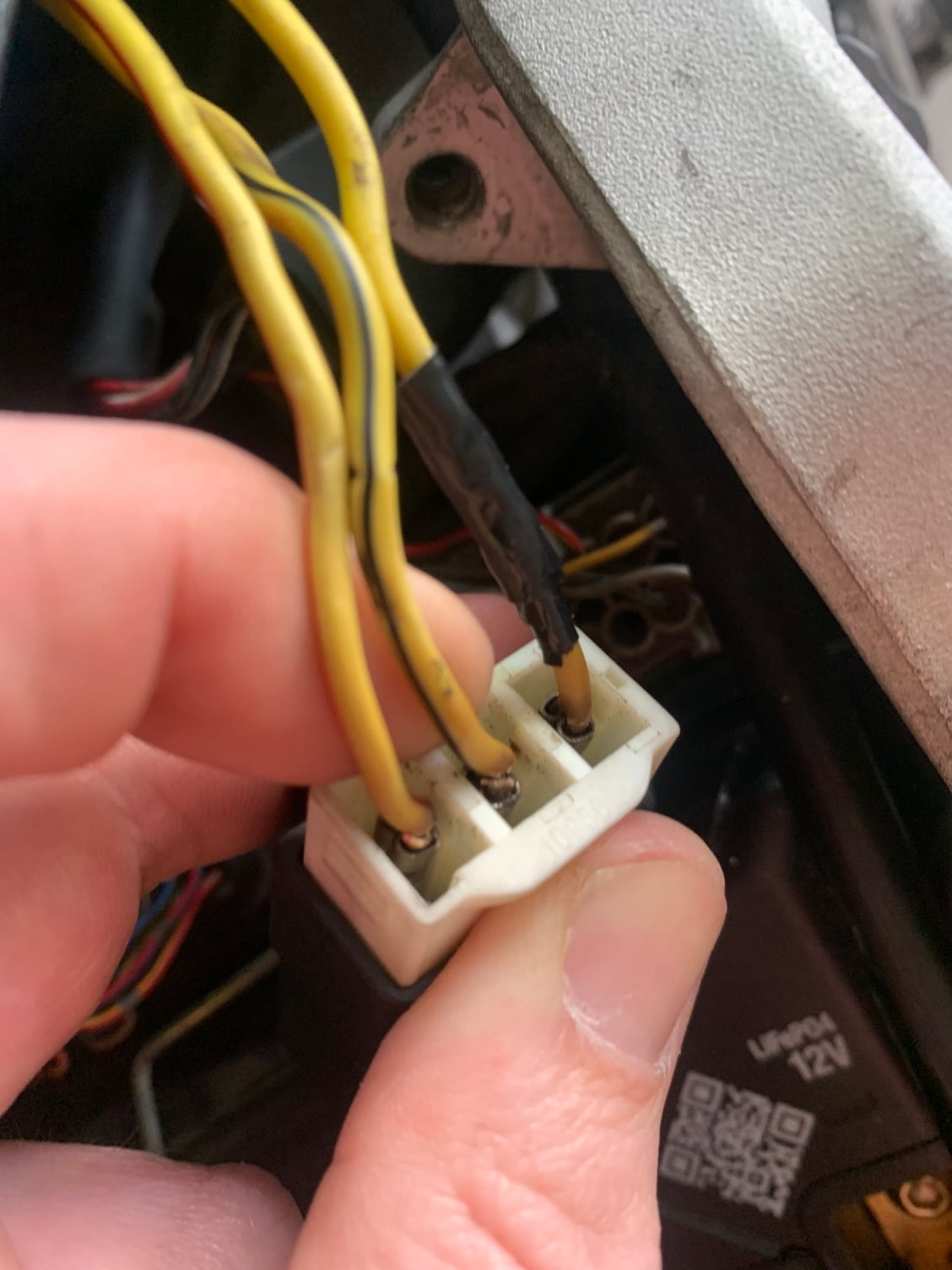

and only thing I could put back on is the kill switch and the other rectifier and I put in a new starter solenoid didnít help anything but ok I disconnected the computer and the kill switch was on and tuned key on with new fuse didnít blow plugged the computer back in didnít blow then I dipoles the kill switch to off then back on and it blew the fuse and I send a pic of the crap job they did to the taillights but somehow they still worked before the battery blew but now I got a new stator and the old ones trashed but it had wires burnt up and sticking out of it so surprised it worked these next pics are from the old stator wires

and more and more I get into the bike **** bolts missin like the only three bolts in the stator case should be four

and only thing I can put back are thos and the kill switch

and when I hit my back breaks the taillights do a triple flash idk wher the flasher part is unless itís in all that wiring in the taillight area but itís all just cut wires and u think i should cut the taillights to disconnect cuz dude I got it from didnít use any clip-ins and there no bulbs in this taillights itís a led computer looking board inside the tail

lights

Last edited by Joe515; 08-20-2023 at 07:27 PM.

#32

Danny will know more, but if we assume the computer is good, then when you turn the kill switch on, that energizes the coil packs, the fuel pump, and the bank angle sensor - I *think* everything else is energized just by turning the ignition on.

So unplug those things and see if the fuse blows still.

Personally, I'd pull all the fuses from the bike except the main one, and see if it still blows, then I'd replace them one by one in the hope that would narrow down which circuit is shorting to ground. There is likely a more refined troubleshooting process though.

So unplug those things and see if the fuse blows still.

Personally, I'd pull all the fuses from the bike except the main one, and see if it still blows, then I'd replace them one by one in the hope that would narrow down which circuit is shorting to ground. There is likely a more refined troubleshooting process though.

#33

Danny will know more, but if we assume the computer is good, then when you turn the kill switch on, that energizes the coil packs, the fuel pump, and the bank angle sensor - I *think* everything else is energized just by turning the ignition on.

So unplug those things and see if the fuse blows still.

Personally, I'd pull all the fuses from the bike except the main one, and see if it still blows, then I'd replace them one by one in the hope that would narrow down which circuit is shorting to ground. There is likely a more refined troubleshooting process though.

So unplug those things and see if the fuse blows still.

Personally, I'd pull all the fuses from the bike except the main one, and see if it still blows, then I'd replace them one by one in the hope that would narrow down which circuit is shorting to ground. There is likely a more refined troubleshooting process though.

The following users liked this post:

Al1040 (08-22-2023)

#34

You've got really screwed up wiring on this bike!!! My suggestion is to buy brand-new factory OEM wiring-harness from authorised Honda dealer. Remove existing harness and install new one. ANY aftermarket crap that doesn't plug directly into harness, remove and toss. This is only way you can be 100% sure harness is working properly.

If you want to try and fix existing harness, there's many steps that needs to be done.

First, remove ALL aftermarket wiring from harness to restore it back to 100% factory OEM condition. Unwrap ALL tape hiding hacking and molestation:

For all those dangling segments of wiring that's not connected to anything, trim them off as close to factory wiring as possible. Then verify there's no damage to factory wiring at that spot. Re-cover with better electrical tape. Repeat for every section that has been hacked and damaged. We want to restore harness back to 100% factory OEM condition like when it left factory.

Trace where that blk/red ground wire that's clamped under bolt goes.

Next, since that 20a FI fuse powers entire EFI system we need to test and measure every single wire in EFI circuit to verify it's good and not shorted. Since you're not Superman and can't see electrons flowing inside wires, there's absolutely zero way any human can just look at wires and determine their ability to conduct or not conduct electricity. Luckily, we have instruments that can. This is 5-minute fix with multimeter... or less in many cases...

Get yourself a multimeter. https://www.harborfreight.com/7-func...ter-63759.html

Coupons here: http://www.hfqpdb.com/browse

Learn to use multimeter to measure resistance and voltage: https://learn.sparkfun.com/tutorials...multimeter/all

Next, we'll troubleshoot why 20a FI fuse is blowing by systematically measuring entire EFI circuitry:

PREPARE FOR METER READINGS

1. pull headlight fuse and connect trickle-charger so we don't kill battery

2. pull 20a FI fuse, no need to blow 10,000 of these things without getting any helpful data or results

3. set multimeter to lowest resistance range, 200-ohms

4. clamp blk probe to -neg terminal of battery

5. touch red probe to outlet terminal/socket of fuse-holder

6. key ON, kill=RUN

7. what resistance reading do you get on meter? Low-value indicates short to ground of power-wire.

DISCONNECT END-COMPONENTS FROM EFI CIRCUIT

Systematically disconnect EFI components starting from furthest end-point, while monitoring meter's reading. IF meter changes to OL - open loop or 1, we know that move recent removed part was causing short. Not likely, 99.99% of time, all parts are perfectly fine. But this is 1st stage in troubleshooting, so we can get to next.

8. Disconnect servo-buddy, does meter reading change?

9. disconnect ECU, does meter reading change?

10.. disconnect purge-control solenoid valve

11. disconnect O2-sensor

12. disconnect exhaust-air injection solenoid valve

13. disconnect each ignition-coil

14. disconnect ignition-coil sub-harness

15. disconnect each injector

16. disconnect injector sub-harness

17. disconnect fuel-pump

18. disconnect fuel-pump relay

19. disconnect engine-stop relay

After all these components have been disconnected, and meter-reading still shows low-ohms, short-circuit, we’ll measure each wiring-segment for shorts. Since some segments are connected in parallel, no way to measure individually, so we’ll manually trace.

19. measure resistance end-to-end of red/wht wire between fuse-outlet terminal to engine-stop relay socket input

20. Unwrap and trace EFI main-power blk/wht (purple on diagram), from engine-stop relay socket output to ECU connector. Look for melted insulation with exposed conductor inside. Follow each (T or Y splits) of wire, should have ONLY following connections:

brn input to fuel-cut relay

blk/wht input to fuel-cut relay

blk/wht power to injector sub-harness

blk/wht power to exhaust air injection solenoid valve

blk/wht power to O2-sensor

blk/wht power to ignition-coil sub-harness connector

blk/wht power to purge control solenoid valve

At some point when inspecting entire length of all these wires, you’ll find one of 2 things:

melted/frayed wire touching frame or other wires

unauthorised connection of blk/wht power wire to some other wire that it’s not supposed to be connected to

Disconnect this unauthorised connection, repair and tape over factory harness wire and FI fuse will stop blowing and bike will run!

If you want to try and fix existing harness, there's many steps that needs to be done.

First, remove ALL aftermarket wiring from harness to restore it back to 100% factory OEM condition. Unwrap ALL tape hiding hacking and molestation:

For all those dangling segments of wiring that's not connected to anything, trim them off as close to factory wiring as possible. Then verify there's no damage to factory wiring at that spot. Re-cover with better electrical tape. Repeat for every section that has been hacked and damaged. We want to restore harness back to 100% factory OEM condition like when it left factory.

Trace where that blk/red ground wire that's clamped under bolt goes.

Next, since that 20a FI fuse powers entire EFI system we need to test and measure every single wire in EFI circuit to verify it's good and not shorted. Since you're not Superman and can't see electrons flowing inside wires, there's absolutely zero way any human can just look at wires and determine their ability to conduct or not conduct electricity. Luckily, we have instruments that can. This is 5-minute fix with multimeter... or less in many cases...

Get yourself a multimeter. https://www.harborfreight.com/7-func...ter-63759.html

Coupons here: http://www.hfqpdb.com/browse

Learn to use multimeter to measure resistance and voltage: https://learn.sparkfun.com/tutorials...multimeter/all

Next, we'll troubleshoot why 20a FI fuse is blowing by systematically measuring entire EFI circuitry:

PREPARE FOR METER READINGS

1. pull headlight fuse and connect trickle-charger so we don't kill battery

2. pull 20a FI fuse, no need to blow 10,000 of these things without getting any helpful data or results

3. set multimeter to lowest resistance range, 200-ohms

4. clamp blk probe to -neg terminal of battery

5. touch red probe to outlet terminal/socket of fuse-holder

6. key ON, kill=RUN

7. what resistance reading do you get on meter? Low-value indicates short to ground of power-wire.

DISCONNECT END-COMPONENTS FROM EFI CIRCUIT

Systematically disconnect EFI components starting from furthest end-point, while monitoring meter's reading. IF meter changes to OL - open loop or 1, we know that move recent removed part was causing short. Not likely, 99.99% of time, all parts are perfectly fine. But this is 1st stage in troubleshooting, so we can get to next.

8. Disconnect servo-buddy, does meter reading change?

9. disconnect ECU, does meter reading change?

10.. disconnect purge-control solenoid valve

11. disconnect O2-sensor

12. disconnect exhaust-air injection solenoid valve

13. disconnect each ignition-coil

14. disconnect ignition-coil sub-harness

15. disconnect each injector

16. disconnect injector sub-harness

17. disconnect fuel-pump

18. disconnect fuel-pump relay

19. disconnect engine-stop relay

After all these components have been disconnected, and meter-reading still shows low-ohms, short-circuit, we’ll measure each wiring-segment for shorts. Since some segments are connected in parallel, no way to measure individually, so we’ll manually trace.

19. measure resistance end-to-end of red/wht wire between fuse-outlet terminal to engine-stop relay socket input

20. Unwrap and trace EFI main-power blk/wht (purple on diagram), from engine-stop relay socket output to ECU connector. Look for melted insulation with exposed conductor inside. Follow each (T or Y splits) of wire, should have ONLY following connections:

brn input to fuel-cut relay

blk/wht input to fuel-cut relay

blk/wht power to injector sub-harness

blk/wht power to exhaust air injection solenoid valve

blk/wht power to O2-sensor

blk/wht power to ignition-coil sub-harness connector

blk/wht power to purge control solenoid valve

At some point when inspecting entire length of all these wires, you’ll find one of 2 things:

melted/frayed wire touching frame or other wires

unauthorised connection of blk/wht power wire to some other wire that it’s not supposed to be connected to

Disconnect this unauthorised connection, repair and tape over factory harness wire and FI fuse will stop blowing and bike will run!

Last edited by dannoxyz; 08-22-2023 at 11:31 PM.

#35

You've got really screwed up wiring on this bike!!! My suggestion is to buy brand-new factory OEM wiring-harness from authorised Honda dealer. Remove existing harness and install new one. ANY aftermarket crap that doesn't plug directly into harness, remove and toss. This is only way you can be 100% sure harness is working properly.

If you want to try and fix existing harness, there's many steps that needs to be done.

First, remove ALL aftermarket wiring from harness to restore it back to 100% factory OEM condition. Unwrap ALL tape hiding hacking and molestation:

For all those dangling segments of wiring that's not connected to anything, trim them off as close to factory wiring as possible. Then verify there's no damage to factory wiring at that spot. Re-cover with better electrical tape. Repeat for every section that has been hacked and damaged. We want to restore harness back to 100% factory OEM condition like when it left factory.

Trace where that blk/red ground wire that's clamped under bolt goes.

Next, since that 20a FI fuse powers entire EFI system we need to test and measure every single wire in EFI circuit to verify it's good and not shorted. Since you're not Superman and can't see electrons flowing inside wires, there's absolutely zero way any human can just look at wires and determine their ability to conduct or not conduct electricity. Luckily, we have instruments that can. This is 5-minute fix with multimeter... or less in many cases...

Get yourself a multimeter. https://www.harborfreight.com/7-func...ter-63759.html

Coupons here: Harbor Freight Tools Coupon Database - Free coupons, 25 percent off coupons, 20 percent off coupons, No Purchase Required coupons, toolbox coupons

Learn to use multimeter to measure resistance and voltage: https://learn.sparkfun.com/tutorials...multimeter/all

Next, we'll troubleshoot why 20a FI fuse is blowing by systematically measuring entire EFI circuitry:

PREPARE FOR METER READINGS

1. pull headlight fuse and connect trickle-charger so we don't kill battery

2. pull 20a FI fuse, no need to blow 10,000 of these things without getting any helpful data or results

3. set multimeter to lowest resistance range, 200-ohms

4. clamp blk probe to -neg terminal of battery

5. touch red probe to outlet terminal/socket of fuse-holder

6. key ON, kill=RUN

7. what resistance reading do you get on meter? Low-value indicates short to ground of power-wire.

DISCONNECT END-COMPONENTS FROM EFI CIRCUIT

Systematically disconnect EFI components starting from furthest end-point, while monitoring meter's reading. IF meter changes to OL - open loop or 1, we know that move recent removed part was causing short. Not likely, 99.99% of time, all parts are perfectly fine. But this is 1st stage in troubleshooting, so we can get to next.

8. Disconnect servo-buddy, does meter reading change?

9. disconnect ECU, does meter reading change?

10.. disconnect purge-control solenoid valve

11. disconnect O2-sensor

12. disconnect exhaust-air injection solenoid valve

13. disconnect each ignition-coil

14. disconnect ignition-coil sub-harness

15. disconnect each injector

16. disconnect injector sub-harness

17. disconnect fuel-pump

18. disconnect fuel-pump relay

19. disconnect engine-stop relay

After all these components have been disconnected, and meter-reading still shows low-ohms, short-circuit, weíll measure each wiring-segment for shorts. Since some segments are connected in parallel, no way to measure individually, so weíll manually trace.

19. measure resistance end-to-end of red/wht wire between fuse-outlet terminal to engine-stop relay socket input

20. Unwrap and trace EFI main-power blk/wht (purple on diagram), from engine-stop relay socket output to ECU connector. Look for melted insulation with exposed conductor inside. Follow each (T or Y splits) of wire, should have ONLY following connections:

brn input to fuel-cut relay

blk/wht input to fuel-cut relay

blk/wht power to injector sub-harness

blk/wht power to exhaust air injection solenoid valve

blk/wht power to O2-sensor

blk/wht power to ignition-coil sub-harness connector

blk/wht power to purge control solenoid valve

At some point when inspecting entire length of all these wires, youíll find one of 2 things:

melted/frayed wire touching frame or other wires

unauthorised connection of blk/wht power wire to some other wire that itís not supposed to be connected to

Disconnect this unauthorised connection, repair and tape over factory harness wire and FI fuse will stop blowing and bike will run!

If you want to try and fix existing harness, there's many steps that needs to be done.

First, remove ALL aftermarket wiring from harness to restore it back to 100% factory OEM condition. Unwrap ALL tape hiding hacking and molestation:

For all those dangling segments of wiring that's not connected to anything, trim them off as close to factory wiring as possible. Then verify there's no damage to factory wiring at that spot. Re-cover with better electrical tape. Repeat for every section that has been hacked and damaged. We want to restore harness back to 100% factory OEM condition like when it left factory.

Trace where that blk/red ground wire that's clamped under bolt goes.

Next, since that 20a FI fuse powers entire EFI system we need to test and measure every single wire in EFI circuit to verify it's good and not shorted. Since you're not Superman and can't see electrons flowing inside wires, there's absolutely zero way any human can just look at wires and determine their ability to conduct or not conduct electricity. Luckily, we have instruments that can. This is 5-minute fix with multimeter... or less in many cases...

Get yourself a multimeter. https://www.harborfreight.com/7-func...ter-63759.html

Coupons here: Harbor Freight Tools Coupon Database - Free coupons, 25 percent off coupons, 20 percent off coupons, No Purchase Required coupons, toolbox coupons

Learn to use multimeter to measure resistance and voltage: https://learn.sparkfun.com/tutorials...multimeter/all

Next, we'll troubleshoot why 20a FI fuse is blowing by systematically measuring entire EFI circuitry:

PREPARE FOR METER READINGS

1. pull headlight fuse and connect trickle-charger so we don't kill battery

2. pull 20a FI fuse, no need to blow 10,000 of these things without getting any helpful data or results

3. set multimeter to lowest resistance range, 200-ohms

4. clamp blk probe to -neg terminal of battery

5. touch red probe to outlet terminal/socket of fuse-holder

6. key ON, kill=RUN

7. what resistance reading do you get on meter? Low-value indicates short to ground of power-wire.

DISCONNECT END-COMPONENTS FROM EFI CIRCUIT

Systematically disconnect EFI components starting from furthest end-point, while monitoring meter's reading. IF meter changes to OL - open loop or 1, we know that move recent removed part was causing short. Not likely, 99.99% of time, all parts are perfectly fine. But this is 1st stage in troubleshooting, so we can get to next.

8. Disconnect servo-buddy, does meter reading change?

9. disconnect ECU, does meter reading change?

10.. disconnect purge-control solenoid valve

11. disconnect O2-sensor

12. disconnect exhaust-air injection solenoid valve

13. disconnect each ignition-coil

14. disconnect ignition-coil sub-harness

15. disconnect each injector

16. disconnect injector sub-harness

17. disconnect fuel-pump

18. disconnect fuel-pump relay

19. disconnect engine-stop relay

After all these components have been disconnected, and meter-reading still shows low-ohms, short-circuit, weíll measure each wiring-segment for shorts. Since some segments are connected in parallel, no way to measure individually, so weíll manually trace.

19. measure resistance end-to-end of red/wht wire between fuse-outlet terminal to engine-stop relay socket input

20. Unwrap and trace EFI main-power blk/wht (purple on diagram), from engine-stop relay socket output to ECU connector. Look for melted insulation with exposed conductor inside. Follow each (T or Y splits) of wire, should have ONLY following connections:

brn input to fuel-cut relay

blk/wht input to fuel-cut relay

blk/wht power to injector sub-harness

blk/wht power to exhaust air injection solenoid valve

blk/wht power to O2-sensor

blk/wht power to ignition-coil sub-harness connector

blk/wht power to purge control solenoid valve

At some point when inspecting entire length of all these wires, youíll find one of 2 things:

melted/frayed wire touching frame or other wires

unauthorised connection of blk/wht power wire to some other wire that itís not supposed to be connected to

Disconnect this unauthorised connection, repair and tape over factory harness wire and FI fuse will stop blowing and bike will run!

The following users liked this post:

dannoxyz (09-10-2023)

#36

hey thanks guys but Iím just a beginner Iím tryin to figure it out I appreciate it I prolly have to take it to a shop cuz I only got two days to work on the bike cuz work and kid and Iím not sure how to get readings on the meter I got I been watching YouTube to try to learn I live in Ohio around Chillicothe and Columbus if anyone on here knows of a good Mechanic that I can go to id appreciate it

Thread

Thread Starter

Forum

Replies

Last Post