Fuel pump point switch

#1

I had stuff packed for a long ride for two days, and a hotel room already reserved. Sun was shining. I Started the bike and went on the road with a big grin. That joy lasted only 10 minutes and 11 km. This summer seems to be cursed what comes to riding.

It was the fuel pump point switch that failed me - once again.

The original switch lasted for about 50 000 km. I changed the switch to an aftermarket part branded "tourmax" which should be "made in Japan" quality. I have my doubts on that because this part lasted less than 7000 km! The points were eaten away as much as the originals were on a far longer period.

What do you quys think, is there any better parts available or are they all the same? How long have your switches lasted and what is their brand?

I wouldn't like to repair the pump every summer. A Complete new original pump would be good, but that costs a lot.

Does anyone know if it's possible to swap the pump to a totally different type - something more reliable?

It was the fuel pump point switch that failed me - once again.

The original switch lasted for about 50 000 km. I changed the switch to an aftermarket part branded "tourmax" which should be "made in Japan" quality. I have my doubts on that because this part lasted less than 7000 km! The points were eaten away as much as the originals were on a far longer period.

What do you quys think, is there any better parts available or are they all the same? How long have your switches lasted and what is their brand?

I wouldn't like to repair the pump every summer. A Complete new original pump would be good, but that costs a lot.

Does anyone know if it's possible to swap the pump to a totally different type - something more reliable?

#2

You might look at the pump itself and at your R/R. Burned up contacts might be the symptom of a worn out pump that is drawing too much current or a failing regulator (or bad R/R connectors) that is delivering too little voltage. I found the upgrade to a MOSFET R/R made a big difference on a lot of the electrical stuff on my F1.

#3

R/R seems to work fine. I measured constant 14.5V charging voltage at both low revs and high revs.

I checked the pump without point switch. The piston moves freely out and in when pulled with grips. I also measured the resistance of the pump - it was 2.0 ohms. Is that OK? Continuity/diode test was beeping in both directions.

I tried the pump action by poking its wires directly to battery terminals. The piston pops out fine when connection is made. But every time the wire is disconnected it makes a clearly visible spark, sometimes with a tiny puff of smoke. Maybe that is a bad sign?

The pump was connected to the battery in total of about 20 seconds. In that time it heated up a bit. Not like burning hot, but obviously warmer than my own hands.

I checked the pump without point switch. The piston moves freely out and in when pulled with grips. I also measured the resistance of the pump - it was 2.0 ohms. Is that OK? Continuity/diode test was beeping in both directions.

I tried the pump action by poking its wires directly to battery terminals. The piston pops out fine when connection is made. But every time the wire is disconnected it makes a clearly visible spark, sometimes with a tiny puff of smoke. Maybe that is a bad sign?

The pump was connected to the battery in total of about 20 seconds. In that time it heated up a bit. Not like burning hot, but obviously warmer than my own hands.

#4

Sounds like the R/R is in good shape. Might be that testing the flow of the pump would yield some info. If it's running weak and switching on and off too often maybe that could wear the points quicker than normal? Pump should flow around 650cc per minute. Usual procedure is run pump into a measuring cup for 5 sec and measure the amount of fuel it puts out, then multiply result by 12 for cc/minute.

And maybe a good cleaning of the fuel relay and pump electrical connections would help.

And maybe a good cleaning of the fuel relay and pump electrical connections would help.

#5

The fuel cut off relay is working OK with good voltage. I connected a 55W bulb to the pump connector instead of the pump. It shined very brightly.

I will do the flow test later today.

if the pump is still in good condition, I think I will add a Mosfet controller to it - with new point switch. That should eliminate all sparking and provide very long lifetime.

Here is great info about the Mosfet switch mod, altough I think it might be better to wire the Mosfet outside of the pump cap and with proper heat sink:

Mitsubishi Pump Conversion Kit

I'm astonished this unreliable pump has been used for so long in the production. From old Honda's since 1986 to much newer KTM's until 2008!

edit: I found even better instructions for the mosfet mod:

http://advrider.com/index.php?thread...mp-diy.414864/

I will do the flow test later today.

if the pump is still in good condition, I think I will add a Mosfet controller to it - with new point switch. That should eliminate all sparking and provide very long lifetime.

Here is great info about the Mosfet switch mod, altough I think it might be better to wire the Mosfet outside of the pump cap and with proper heat sink:

Mitsubishi Pump Conversion Kit

I'm astonished this unreliable pump has been used for so long in the production. From old Honda's since 1986 to much newer KTM's until 2008!

edit: I found even better instructions for the mosfet mod:

http://advrider.com/index.php?thread...mp-diy.414864/

Last edited by Wesku79; 08-24-2015 at 06:55 AM.

#6

Update

There is nothing wrong with the pump itself. I tested the flow rate while keeping petcock and fuel filter in line. I got 500cc in exactly 15 sec. That makes 2 litres/min -> 120 litres/hour. That's many times more than enough, and matches the specs that i have seen on many sites. Also the internal check valve of the pump was working perfectly. When it's outlet was blocked pumping stopped immediately.

My conclusion is that at least some of the aftermarket point switches are compelete crap.

So, I think Mosfet mod with a new switch is the way to go.

At advrider.com forums there is a guy who sells a repair kit which doesn't need point switch at all. It detects the piston rod optically. BUT his mod is designed only for KTM's. It could probably work with Honda's too, but he can't give any quarentee.

There is nothing wrong with the pump itself. I tested the flow rate while keeping petcock and fuel filter in line. I got 500cc in exactly 15 sec. That makes 2 litres/min -> 120 litres/hour. That's many times more than enough, and matches the specs that i have seen on many sites. Also the internal check valve of the pump was working perfectly. When it's outlet was blocked pumping stopped immediately.

My conclusion is that at least some of the aftermarket point switches are compelete crap.

So, I think Mosfet mod with a new switch is the way to go.

At advrider.com forums there is a guy who sells a repair kit which doesn't need point switch at all. It detects the piston rod optically. BUT his mod is designed only for KTM's. It could probably work with Honda's too, but he can't give any quarentee.

#7

The conversion is a neat idea. I would probably consider the warning by one guy of solder melting. In spite of what the author says, I have seen high current capable semiconductors get hot enough to melt the solder connections before the device fails. One should also bear in mind that max current ratings on MOSFETS and the like are usually based upon a certain amount of heat sinking and they may not fare too well at max current if not tabbed to a sink. The M3 screw will not conduct much heat away, particularly into a plastic cap... Steel is a crappy thermal conductor and the contact area between the screw thread and the hole in the tab is tiny.

I agree that it makes sense to put the FET outside the cover. I would try to emulate the way an R/R is mounted. Get a good sized heat sink, attach the FET to it with a good thermal pad kit (Sil Pad or mica) so the heat sink won't short it out if it touches the chassis, and route the appropriate wires out of the cap to the FET. Insulate and weatherproof the connections with heat shrink and maybe high temp silicone goop where necessary. Mount the heat sink where it will catch some air.

I agree that it makes sense to put the FET outside the cover. I would try to emulate the way an R/R is mounted. Get a good sized heat sink, attach the FET to it with a good thermal pad kit (Sil Pad or mica) so the heat sink won't short it out if it touches the chassis, and route the appropriate wires out of the cap to the FET. Insulate and weatherproof the connections with heat shrink and maybe high temp silicone goop where necessary. Mount the heat sink where it will catch some air.

#8

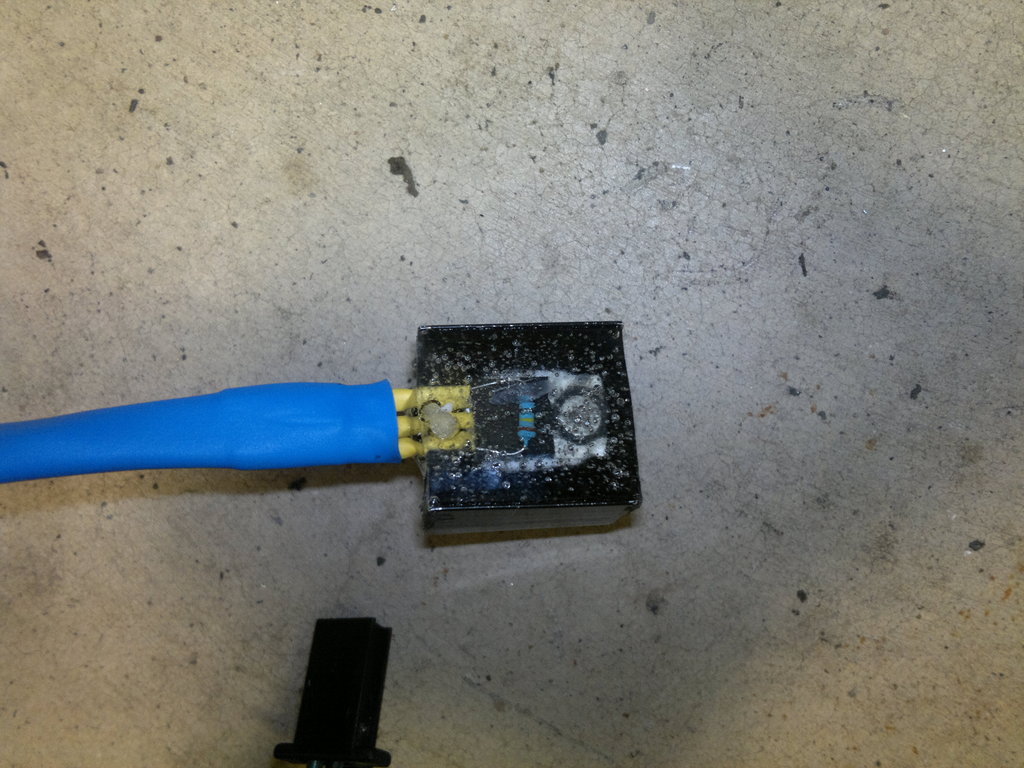

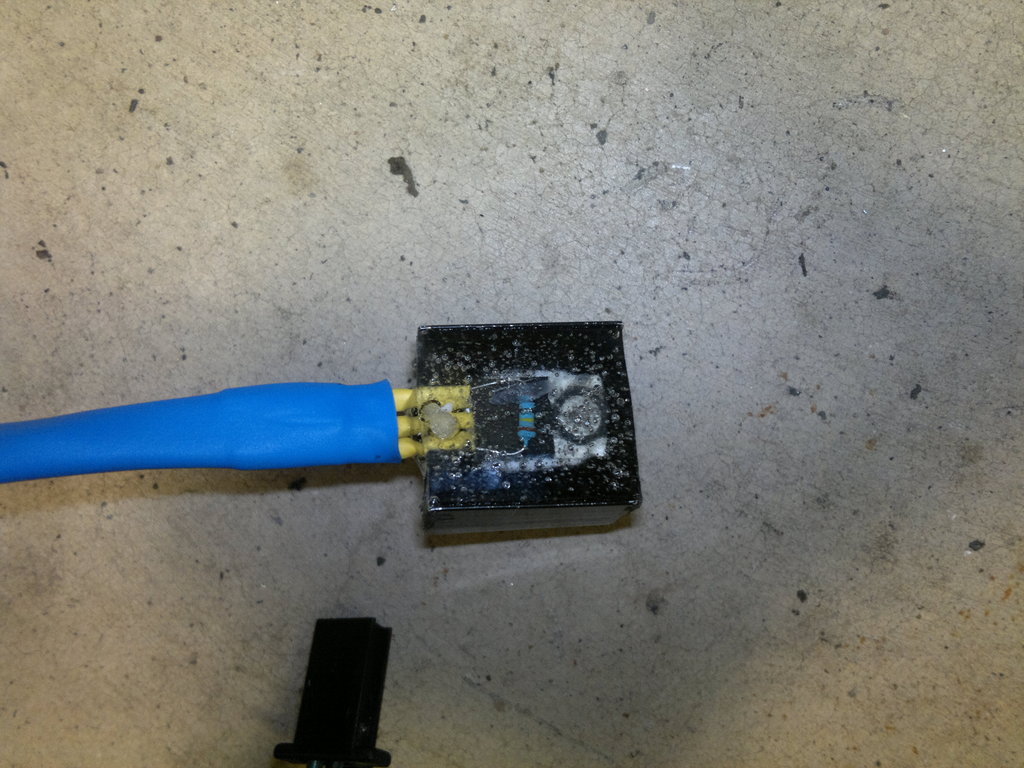

I got the mod done few days ago. I made remote wiring to the FET and mounted it to a small heat sink. Then I sealed the package by pouring epoxy resin on it.

I think it's easier to solder all the components this way than trying to fit everything under the plastic cap. There is not very much room in there.

The FET is located behind fuel filter, fixed at side of battery tray.

This mod works perfectly so far. The pump is ticking as it's supposed to. Fuel supply is sufficient at max revs. After test drive I touched the heat sink. It gets only lukewarm - definitely not going to melt any solderings.

As you can see in the first picture, I forgot to pass heat shrink tube over the main wires, doh! I didn't bother to solder the connector again. I hope insulating tape wrapping will do as there is no sharp corners on it's way.

I think it's easier to solder all the components this way than trying to fit everything under the plastic cap. There is not very much room in there.

The FET is located behind fuel filter, fixed at side of battery tray.

This mod works perfectly so far. The pump is ticking as it's supposed to. Fuel supply is sufficient at max revs. After test drive I touched the heat sink. It gets only lukewarm - definitely not going to melt any solderings.

As you can see in the first picture, I forgot to pass heat shrink tube over the main wires, doh! I didn't bother to solder the connector again. I hope insulating tape wrapping will do as there is no sharp corners on it's way.

Thread

Thread Starter

Forum

Replies

Last Post

Kopi Ko

F4i - Main Forum

16

10-01-2019 08:29 AM